Troubleshooting Common Heat Pump Problems: Expert Solutions for Heating, Freezing, Noise, and Efficiency Issues

A heat pump acting up can really mess with your home’s comfort and send your energy bills soaring. This guide to heat pump troubleshooting breaks down why your system might not be heating, why it’s freezing over, making strange noises, or running too much. We’ll cover simple checks, maintenance tips, and when it’s time to call in the pros. You’ll learn how your thermostat, filters, refrigerant, and airflow all play a part in how well your system works. Plus, you’ll discover some safe DIY checks and understand when Northside Services’ expert repair and diagnostic skills are exactly what you need for lasting relief. We’re diving into seven key areas: no heat, freezing issues, odd sounds, short cycling, at-home diagnostics, proactive care, and professional help, so you can get your Florida home or business back to comfortable temperatures.

Why Is My Heat Pump Not Heating? Common Causes and Fixes

When your heat pump isn’t delivering warm air, it’s a clear sign something’s off with its heating cycle. A heat pump relies on a steady flow of refrigerant, accurate signals from your thermostat, clean airflow, and sufficient electrical power to work. If any of these components aren’t performing right, heat transfer suffers, and your home gets chilly. Knowing the common symptoms and what each part does can help you figure out why your heat pump isn’t heating and get it back on track.

What Are the Key Symptoms of a Heat Pump Not Heating?

You might notice your heat pump isn’t heating if there’s no warm air coming from your vents, the system runs for a long time without warming up your home, or you see unusual frost on the outdoor unit. Other signs include the fan running constantly without any heat, weak airflow, or sudden temperature drops inside. Catching these signs early can prevent further damage to critical parts like the compressor and reversing valve, which could lead to expensive repairs.

How Do Thermostat Issues Affect Heat Pump Heating?

A thermostat that’s out of calibration or not working correctly can stop your heat pump service from heating properly by failing to send the right signals. This control unit is responsible for telling the compressor when to turn on based on your desired temperature. If the thermostat’s sensor is misaligned or the wiring is loose, your heat pump might stay off or run in cooling mode. Often, simply changing the batteries, making sure the thermostat isn’t near a draft, or checking the wiring can get it sending the correct heating commands again.

Can Dirty Air Filters Cause Heating Problems?

When air filters get clogged, they restrict airflow, making your heat pump less efficient at transferring heat and putting extra strain on the blower motor. This can lead to lower indoor temperatures, reduced system capacity, and even overload your compressor. Swapping out or cleaning your filters every one to three months helps improve heat transfer, makes your home more comfortable, and prevents coil icing and motor wear, extending the life of your components.

How Does Low Refrigerant Level Reduce Heat Output?

If your heat pump doesn’t have enough refrigerant, it can’t effectively absorb heat in the evaporator coil. This forces the compressor to work much harder without producing the warm air you need. Low refrigerant can cause temperature imbalances, lead to ice forming on the coil, and increase your energy usage. Because handling refrigerant requires special training and equipment to protect both you and the environment, it’s a job best left to certified technicians.

What DIY Steps Can I Take to Fix No Heat Issues?

- Swap out or clean the air filter to get airflow back to normal.

- Double-check your thermostat settings to make sure it’s on heat mode and set to the right temperature.

- Look at the outdoor unit for any blockages like debris, leaves, or ice that might be stopping airflow.

- If you suspect an electrical issue, reset your heat pump’s circuit breaker, but only after confirming the circuit is stable.

- Clear away any plants, grass, or other items from around the outdoor unit, ensuring at least half a metre of clear space.

When Should I Call a Professional for Heat Pump Heating Problems?

If you’ve tried these basic checks and your home is still not warming up, it’s time to bring in the heat pump repair experts. If you’re dealing with a persistent lack of heat, suspect refrigerant leaks, electrical problems, or compressor issues, Northside Services has the specialized diagnostic tools and certified technicians to get the job done right. Professional help ensures that refrigerant is handled safely, faults are accurately identified, and repairs are made to last, improving your system’s long-term performance.

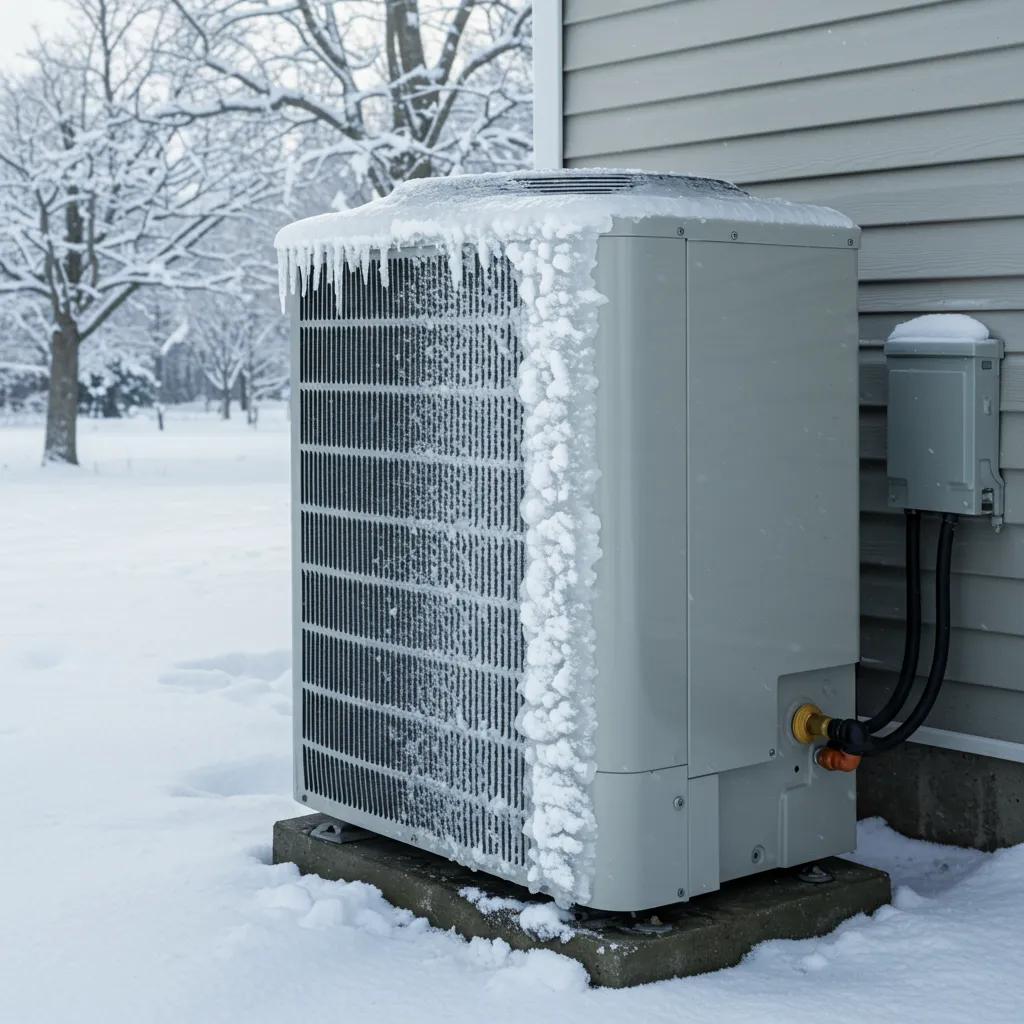

What Causes Heat Pumps to Freeze Up and How Can I Troubleshoot This?

When ice builds up on your heat pump’s coils or refrigerant lines, it’s called freezing, and it stops the system from transferring heat effectively and restricts airflow. Low refrigerant, dirty evaporator coils, a malfunctioning fan motor, or blocked airflow can all cause this to happen, especially in colder weather. Recognizing the signs of a freeze-up and ensuring your system’s defrost cycle is working correctly can prevent damage to the compressor and keep your heating or cooling capacity intact.

Common signs that your heat pump is freezing up include ice forming around the outdoor coil, water leaking from the unit, strange compressor noises during the defrost cycle, and reduced airflow indoors. Catching these issues early can prevent extended downtime and keep your system running reliably.

How Does Low Refrigerant Lead to Freezing?

When refrigerant levels are low, the coils can get colder than they should, often dropping below freezing. This causes frost to form persistently on the evaporator coil. This ice then blocks warm indoor air from circulating, forcing the system to run its defrost cycle more often. These frequent, short defrost cycles can wear out the defrost controls and leave the system stuck in an icy state. A qualified technician needs to find and fix any leaks, repair the lines, and recharge the refrigerant to get the heat exchange and defrost functions working properly again.

Can Dirty Evaporator Coils Cause Ice Build-Up?

Dirt and grime on your evaporator coils act like an insulator, making the coil surface colder and more likely to form frost. When heat can’t be absorbed efficiently, the system might go into longer defrost cycles, allowing thick layers of ice to accumulate. Having a professional clean your coils, or using safe cleaning solutions, can remove these obstructions, allowing the coils to maintain their proper operating temperatures and significantly reducing the risk of freezing.

What Role Does Fan Motor Malfunction Play in Freezing?

If your heat pump’s fan motor isn’t working correctly, it slows down the airflow across the coils. This leads to uneven heating and cold spots where moisture can freeze. Insufficient airflow means the coil doesn’t get warm enough, allowing ice to build up. Sometimes, just lubricating the motor, checking the belt, or replacing a worn-out motor can restore consistent airflow, balance coil temperatures, and prevent ice from forming.

How Does Blocked Airflow Contribute to Freezing Issues?

When things like leaves, grass clippings, or other debris pile up around your outdoor unit, they block the free movement of air that’s essential for proper heat exchange. This restricted airflow causes the coil temperature to drop below freezing, leading to rapid ice accumulation. Keeping the area around your unit clear and trimming back any encroaching vegetation ensures continuous, unobstructed airflow, which is key to your heat pump’s performance.

What Preventative Measures Help Avoid Heat Pump Freezing?

To keep your heat pump from freezing up, make sure to clean the coils regularly, change your filters often, ensure there’s enough clearance around the outdoor unit, and schedule professional tune-ups before the cold weather hits. Annual inspections by Northside Services experts can catch small issues early, adjust defrost settings, and confirm your refrigerant levels are correct. This kind of proactive care helps prevent unexpected freeze-ups and keeps your system running efficiently.

How Do I Identify and Fix Strange Noises Coming from My Heat Pump?

Unusual noises from your heat pump are often a sign that a component is wearing out or the system is out of balance. Sounds like squealing, grinding, bubbling, or clicking can point to specific problems that could become much bigger issues if ignored. Addressing these sounds quickly can help keep your system healthy and prevent you from needing to replace equipment too soon.

What Types of Noises Indicate Specific Heat Pump Problems?

By listening carefully to the different sounds your heat pump makes, you can get a good idea of what might be wrong:

Before you dive into the table below, remember that understanding these noise sources can help guide repairs and stop minor issues from turning into major ones.

| Noise Type | Likely Cause | Recommended Action |

|---|---|---|

| Squealing | Worn belt or bearing | Check and replace the belt or lubricate the motor. |

| Grinding | Damaged bearings | Schedule an inspection for motor or compressor overhaul. |

| Bubbling | Refrigerant leak | Arrange for leak detection and refrigerant recharge. |

| Clicking | Loose electrical relay | Tighten connections or replace the relay. |

This table connects specific sounds to the likely problems and the steps you should take, helping you act fast and get your system running quietly again.

What Does Squealing Noise Mean for Heat Pump Belts?

A squealing sound usually means the drive belts are stretched, worn smooth, or slipping on the pulleys. This not only reduces the blower’s performance but also puts extra stress on the motor bearings. Belt slippage creates friction heat that can quickly damage the belt material. Replacing worn belts and ensuring they have the correct tension will help maintain consistent airflow and stop those annoying squeals.

How to Recognize Grinding Sounds from Bearings?

Grinding noises suggest that metal is rubbing against metal inside the motor couplings or compressor bearings. This is often a sign that the bearings are severely damaged and could lead to them seizing up completely. If you hear grinding, it’s a good idea to have the bearings inspected right away. Addressing this early can save your system’s longevity and prevent the need for a costly compressor replacement.

What Does Bubbling Noise Reveal About Refrigerant Leaks?

If you hear bubbling or gurgling sounds, it often indicates low refrigerant pressure and that the refrigerant is boiling in the lines. Leaks can let air and moisture into the system, which can damage internal parts and affect how well your heat pump transfers heat. Having a professional find and fix the leak, repair the lines, and add the correct amount of refrigerant will restore efficiency and proper operation.

How to Address Clicking Sounds Related to Electrical Issues?

Clicking noises typically come from faulty relays, contactors, or loose wiring that’s causing the electrical circuit to engage intermittently. These sounds can sometimes happen right before the system shuts off completely or triggers a safety shutdown. Tightening electrical connections, checking the control board, and replacing worn-out relays can prevent unexpected shutdowns and ensure electrical safety.

When Is Noise a Sign to Contact a Technician?

If you’ve tried basic troubleshooting and the noises persist, it’s definitely time to call in a professional. Sounds like grinding bearings or indications of refrigerant leaks require specialized tools and expertise to fix safely. Northside Services technicians use advanced diagnostic equipment to pinpoint the exact cause of the noise, make the necessary repairs, and confirm that your system is running quietly and efficiently before they leave.

What Is Heat Pump Short Cycling and How Can I Troubleshoot It?

Short cycling means your heat pump turns on and off repeatedly in quick succession. This not only wastes energy but also puts extra wear and tear on your system. Common culprits include a heat pump that’s too large for your home, dirty coils, refrigerant issues, or a thermostat placed incorrectly. Fixing these underlying problems can lead to more stable temperatures, lower energy bills, and a longer lifespan for your equipment.

Signs of short cycling include your home’s temperature swinging wildly, the compressor kicking on and off frequently, and generally feeling uncomfortable. Catching this early can prevent unnecessary stress on your compressor and potential failure.

What Are the Symptoms of Heat Pump Short Cycling?

If your heat pump is short cycling, you might notice the compressor starting and stopping every few minutes, hear it clicking off abruptly, or experience uneven temperatures throughout your home. These frequent cycles can strain electrical components, increase your energy costs, and accelerate wear on the mechanical parts. Identifying these symptoms early helps keep your system running smoothly and efficiently.

How Does an Oversized Heat Pump Cause Short Cycling?

A heat pump that’s too powerful for the space it’s meant to condition will quickly reach the desired temperature and shut off before it has a chance to complete a full heating or cooling cycle. This constant starting and stopping prevents proper humidity control, leads to noticeable temperature fluctuations, and significantly shortens the life of your compressor. Ensuring your system is correctly sized by an HVAC professional is key to achieving balanced run times and consistent comfort.

Can Dirty Coils Lead to Short Cycling?

When dirt and debris build up on your evaporator or condenser coils, they interfere with heat exchange. This can trick the system’s controls into thinking it’s not performing well, causing it to shut down and restart the compressor prematurely. This imbalance mimics changes in demand and triggers unnecessary cycles. Cleaning your coils restores efficient heat transfer, reducing these unwanted startups and stabilizing your system’s operation.

How Do Refrigerant Issues Trigger Short Cycling?

An incorrect refrigerant charge can cause pressure fluctuations within the system. These pressure changes can mislead the system’s sensors or safety switches, causing the compressor to shut down too early. Whether the system is undercharged or overcharged, both scenarios can lead to erratic pressure readings and trigger multiple safety shutdowns. Having certified technicians accurately charge your refrigerant corrects these pressure issues and prevents frequent cycling.

What Is the Effect of Thermostat Placement on Cycling?

If your thermostat is located too close to a heating or cooling vent, in direct sunlight, or near a draft, it can get inaccurate temperature readings. This can cause the heat pump to cycle on and off unnecessarily to compensate for perceived temperature changes rather than actual room conditions. Moving your thermostat to an interior wall, away from heat sources and direct airflow, allows it to sense the room temperature accurately and promotes longer, more efficient run cycles.

What Steps Can Prevent Heat Pump Short Cycling?

To prevent short cycling, make sure your equipment is properly sized, clean your coils at least once a year, maintain the correct refrigerant levels, and ensure your thermostat is placed correctly. Scheduling regular professional tune-ups with Northside Services guarantees these factors are checked and kept within the manufacturer’s specifications, promoting sustained efficiency and minimizing cycling.

How Can I Perform Effective Heat Pump Diagnostics at Home?

Doing some basic diagnostic checks yourself can help you pinpoint simple issues before you need to call for professional service. Simple tasks like checking your filters, resetting your thermostat, verifying voltage, and measuring airflow can help identify common problems and give technicians valuable information to speed up repairs.

Effective home diagnostics can make your service calls more efficient by helping to focus on the root cause of the problem, which means less downtime and lower repair costs.

What Basic Checks Should I Perform Before Calling a Technician?

- Check your thermostat’s batteries, settings, and make sure it’s set to the correct mode.

- Replace or clean your air filters to ensure unrestricted airflow.

- Inspect your circuit breakers and fuses to see if any have tripped or blown.

- Make sure the outdoor unit is clear of debris and has at least half a metre of space around it.

- Listen for any unusual sounds when the system starts up and while it’s running.

Keeping notes on what you find during these checks can help your technician diagnose the problem faster and order the right parts more accurately.

How to Check and Replace Heat Pump Air Filters?

To maintain your air filters, first find the filter housing, then carefully remove the old filter and check how dusty it is or if it’s damaged. If the filter looks grey or clogged, slide in a new one or a cleaned filter of the exact same size and MERV rating. Properly installing the filter ensures air flows in the correct direction and helps protect your coils, keeping your heat pump running efficiently.

How Do I Reset My Heat Pump Thermostat Safely?

To reset your thermostat, turn your system off, gently remove the thermostat’s faceplate, wait about a minute for the internal electronics to discharge, and then power it back on. This process can clear minor software glitches and recalibrate the temperature settings. Always follow the specific instructions from your thermostat’s manufacturer to avoid damaging the control circuitry.

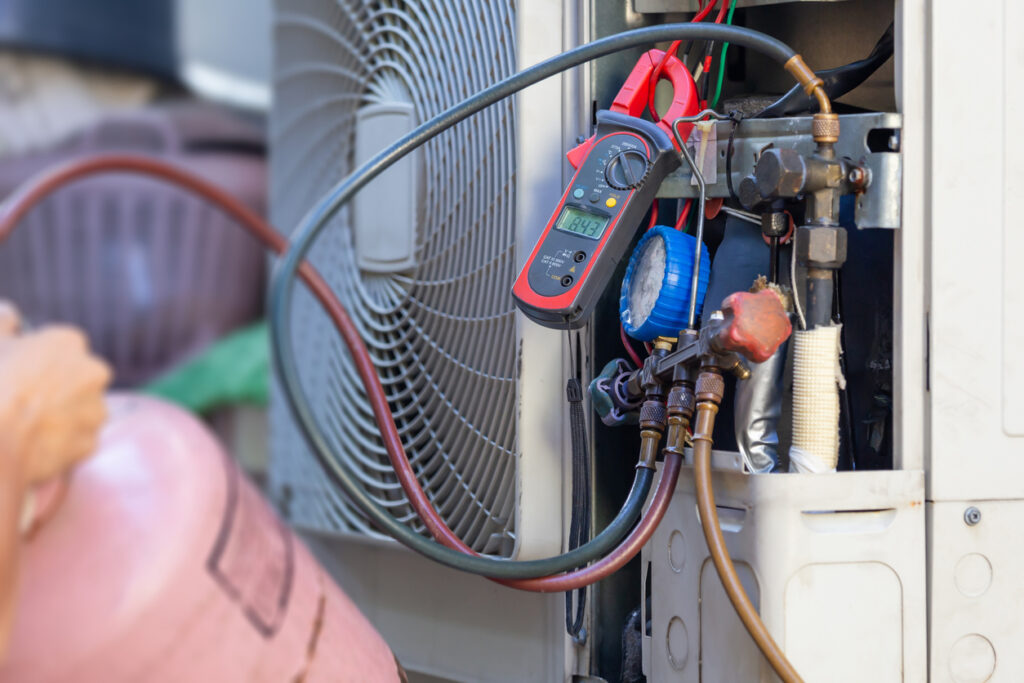

What Tools Are Needed for Simple Heat Pump Diagnostics?

A basic set of diagnostic tools includes a digital multimeter for checking voltage and continuity, a set of refrigerant pressure gauges, an inspection mirror, a flashlight, insulated gloves, and a screwdriver set. These tools allow you to safely measure electrical readings, check refrigerant pressures, and visually inspect internal components.

When Is Professional Diagnostic Service Necessary?

You’ll need professional diagnostics when your initial checks don’t reveal the problem, or if the issue involves handling refrigerant, testing the compressor, or troubleshooting the control board. Northside Services’ certified technicians use advanced diagnostic software and even infrared imaging to pinpoint complex failures and recommend the most precise repairs.

What Are Essential Heat Pump Maintenance Tips to Avoid Common Problems?

Keeping up with regular maintenance can make your heat pump more reliable, lower your energy bills, and extend its lifespan. Simple tasks like changing filters, cleaning coils, ensuring clear space around the outdoor unit, and getting annual inspections can catch small issues before they become major problems. Making these checks part of a routine schedule will help your system perform consistently, especially in Florida’s changing weather.

How Often Should I Replace or Clean Air Filters?

You should check your air filters every month and replace or clean them every one to three months, depending on how dusty your home is and how often your system runs. Clean filters keep airflow steady, protect your coils from getting dirty, and reduce the strain on your blower motor. A consistent filter schedule is key to efficient heat exchange and good indoor air quality.

Why Is Coil Cleaning Important for Heat Pump Efficiency?

When your evaporator and condenser coils get dirty, they act as insulators, making it harder for heat to transfer. This forces your compressor to run longer and work harder. Cleaning your coils restores the proper temperature differences, can lower your energy use by up to 20 percent, and prevents issues like freezing or overheating. Having your coils professionally cleaned once a year ensures that deep-seated debris is removed, maintaining peak efficiency.

How Does Outdoor Unit Clearance Affect Performance?

Keeping at least half a metre of clear space around your outdoor unit is crucial for unobstructed airflow and efficient heat dissipation. When plants, debris, or nearby structures block this space, your unit’s fan struggles to release heat, reducing its overall capacity. Regularly clearing the area around your unit helps your coils release heat effectively and prevents unnecessary cycling or freeze-ups.

What Should Be Included in Annual Heat Pump Inspections?

An annual inspection should always include checking the refrigerant charge, testing safety switches, tightening electrical connections, verifying the defrost cycle is working correctly, and lubricating the blower motor. Technicians will also calibrate your thermostat, inspect your ductwork for leaks, and test all system controls. Comprehensive annual service from Northside Services helps prevent unexpected breakdowns and ensures your system meets manufacturer warranty requirements.

How Does Regular Maintenance Extend Heat Pump Lifespan?

Routine maintenance reduces stress on your heat pump’s main components, prevents premature wear, and keeps the system operating within its optimal performance range. By addressing minor issues before they become costly emergencies, you benefit from improved reliability, lower repair expenses, and can often extend your heat pump maintenance’s lifespan well beyond fifteen years.

When Should I Call a Professional for Heat Pump Repair and Maintenance?

For complex heat pump repairs and even routine maintenance, you often need specialized knowledge, diagnostic tools, and the ability to handle refrigerants safely. Knowing when a problem is beyond a DIY fix ensures your safety, complies with regulations, and leads to a more efficient resolution. Northside Services offers comprehensive heat pump repair, maintenance, and diagnostic services specifically designed for Florida’s climate.

What Complex Repairs Require Certified HVAC Technicians?

Tasks like replacing a compressor, detecting and repairing refrigerant leaks, fixing control boards, or replacing reversing valves require specialized tools and technical certifications. These repairs involve high-pressure refrigerant systems, specific welding techniques, and detailed electrical troubleshooting that are typically beyond the scope of what a homeowner can handle.

Why Is Refrigerant Handling a Job for Experts?

Refrigerant is a pressurized chemical that’s regulated for both environmental protection and system performance. Certified technicians follow strict guidelines to recover, test, and recharge refrigerant without releasing it into the atmosphere. Expert handling ensures the correct type and amount of refrigerant is used, which is vital for your system’s efficiency and for meeting legal requirements.

How Can Northside Services Help with Heat Pump Diagnostics and Repairs?

Northside Services provides expert heat pump repair, maintenance, and diagnostic services across Hillsborough, Pinellas, and Pasco Counties. Our technicians use advanced diagnostic tools, infrared imaging, and the latest industry best practices to pinpoint issues, perform precise repairs, and confirm your system is working perfectly. You can have peace of mind knowing that every repair is backed by reliable expertise and a commitment to customer satisfaction.

What Are the Benefits of Scheduling Regular Professional Maintenance?

Regular professional maintenance can boost your system’s efficiency by up to twenty percent, lower your energy bills, significantly reduce the chance of unexpected breakdowns, and extend the life of your equipment. Scheduled inspections also help maintain manufacturer warranties, improve your home’s comfort, and ensure consistent reliability, even in our humid and variable climate.

How to Contact Northside Services for Heat Pump Service in Florida?

If you need heat pump repair, maintenance, or diagnostic services in Hillsborough, Pinellas, or Pasco Counties, you can easily reach Northside Services through our contact center. Our expert support team is ready to schedule an on-site visit, provide clear assessments of any issues, and ensure your heating and cooling system is restored quickly and reliably.